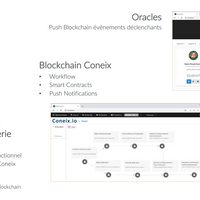

back-office automation

2019 - Blocs & Compagnie - BNP

Back-Office management of mortgage loan applications is a complex process, involving numerous exchanges and documentary checks, and is sensitive as it concludes with the release of funds to the user

This process is unproductive and costly for the bank, and lengthy and frustrating for the user who has very little visibility

Blocs & Compagnie has developed and tested with BNP teams a Blockchain solution for managing and automating documentary flows, resulting in an improvement of key KPIs :

- Processing time

- Processing cost

- Increase in the number of loan requests handled with constant staffing

- Customer satisfaction

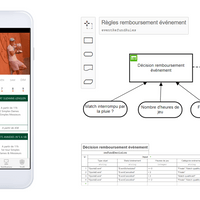

parametric insurance

2019 - Blocs & Compagnie - MAIF

If you subscribe an insurance against weather-related cancellation for a tennis match, you will need to be patient if the event is indeed canceled. There are multiple irritants in the customer journey

- Subscribing to the insurance

- Postal sending of the entry ticket and associated justifications in case of cancellation

- Delays... claims processing is still mostly done by human operators... and the central court of Roland-Garros holds 15,000 seats

Blocs & Compagnie, in partnership with MAIF, has developed a customizable parametric insurance product, managing the entire life cycle of the insurance product

- Subscription

- Automatic triggering of the product if cancellation conditions are met

- Automatic compensation of the client even before they leave the stadium !

Lean manufacturing

2005/2007 - Eurosilicone - GC Aesthetics

The production of breast implants is an extremely manual process, carried out in a clean room, with a very wide variety of products - nearly 2,000 SKUs

Eurosilicone wanted to double its production, with constant workforce and laboratory space, while reducing its non-quality costs and improving its delivery times and customer satisfaction rates

After an upstream study for rationalizing product references, a complete approach to implementing Lean Manufacturing was undertaken on the site without interrupting production

- Reduction of management layers and empowering operators

- Switching supplies to just-in-time and internal Kanban

- Reorganization of different sections of the laboratory

- Overhaul of the logistics circuit

- Support for the teams

industrial turnaround

2002/2005 - 3S - SAB MILLER

Some industrial launches can be disastrous. The brand new 3S site was opened in 1998, recruiting all its staff from the neighboring village. After four years, the site was almost at a standstill, and the production equipment was unusable

An approach to reconstitute the teams and implement best practices was undertaken, allowing the company to resume normal business operations

- Recruitment and organization of maintenance

- Recruitment and training of operators and team leaders

- Reinstallation of part of the production lines

- Implementation of quality and HACCP standards

- Overhaul of the supply-chain process

- Reconquest of the customer base lost during the period

Productivity / agility

production process

1998/2002 - LVMH - Veuve Clicquot Ponsardin

The transition to the year 2000 was not just an IT issue; champagne houses faced two major challenges

- Increasing production volumes to replenish stocks in anticipation of the New Year's Eve celebration on 12/31/1999 - a millennial event !

- Developing special formats and packaging, much more profitable in terms of margin than Non-Vintage Brut bottles

...all in an environment that is both traditional and industrial, requiring a large number of operations for each bottle produced. Thus, the "Maisons" of the LVMH group recruited technical managers from industrial equipment suppliers, with strong experience in industrial performance

Being CTO at VCP (Veuve Clicquot Ponsardin) means overseeing the vineyard and harvesting equipment, the processes and equipment of the winery, the evolution, automation, and maintenance of production lines, the maintenance of the built heritage, the 40 km of cellar galleries and visitor circuits, and interfacing with Marketing for the industrialization of new products...

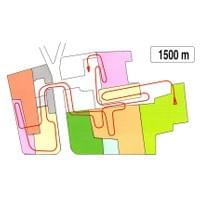

reengineering industrial site

Lean Mfg

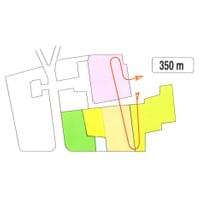

1995/1998 - LEROY-SOMER - EMERSON ELECTRIC

After a VSN (Voluntary Service Overseas) in the USA at the headquarters of Emerson Electric Group, I requested an operational position and was given one... The Leroy Somer site in Sillac, the oldest in the group, set itself the goal of doubling its production capacity in two years, halving its work-in-progress, reducing its manufacturing cycle times by 60%, without interrupting production and while freeing up 30% of building space

A human and exciting project

- Upstream study - flow/dimensioning/buildings/budget

- Complete redesign/reinstallation of production lines

- Management of building/utility projects

- Management of subcontractors for buildings/lines/machines

- Supervision of line/machine relocations

- Implementation of just-in-time using internal kanbans and external software kanbans with suppliers

- Personnel training

...then support for ramping up production by taking responsibility for the assembly workshop, at the end of the production cycle

©2024